While it can last up to 20 years installing torch down roofing can be a dangerous process and as such tends to cost more than traditional roofing materials.

Torch down roofing process.

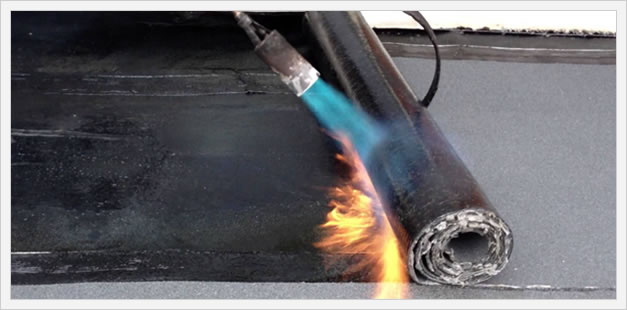

The three foot wide rolls are laid in position and the roofer will begin to apply heat to the exposed portion of the roll and kick it a foot then heat the next exposed portion of the roll and so on see the cover.

The installation of torch down roofing involves the use of a hand held torch fed with propane from a tank.

Torch down roofing is a type of roofing material that has been designed for low angle or flat roofs.

Climb up on a secure ladder with stabilizers that hook onto the roof s edge.

Torch down step by step some trick and tips on how to lay down a torch down roofing.

Hope you like it.

This installation process gives torch down roofing a uniquely watertight seal making it a great choice wherever water damage is a serious concern.

Have someone else nearby in case you need help.

The final result is the vulcanization of a large rubber sheet onto a fiberglass base.

Torch down roofing consists of multiple modified bitumen membranes applied with a propane torch.

Water resistant torch down roofing is an excellent choice in snowy environments.

Any leftover debris can prevent the torch down roofing membrane from forming a waterproof seal so make sure you remove it all before working on the roof.

If a torch down roofing system needs repair it s a relatively simple process.

These extra sheets are torched down in the overlap areas during the installation process using large flame throwing torches that melt the asphalt at the seams to join them together which is the origin of the name torch down roofing.

Stay safe while on the roof.