One of the key layers that has been introduced into fiberglass construction over the last 20 years has been the use of a corrosive resistant vinyl ester layer.

Vinyl ester resin properties.

Vinyl ester resin is a high performance resin that provides improved strength properties and inhibits water penetration into the laminate a process commonly referred to as osmosis.

Ve resins are a combination of both polyester resin and epoxy resins best properties.

Vinyl esters also use peroxides e g.

Bisphenol a based epoxy vinyl ester resins provide high chemical resistance and mechanical strength.

Standard epoxy vinyl ester resins are limited to 220 250 of 104 121 oc in most applications.

While they have high mechanical strength values similar to epoxy resins they are easy to apply similar to unsaturated polyester resins.

Their longer double bonded vinyl groups that link the ester groups together contribute a flexible nature to the resin.

Renewable precursors to vinyl ester resins have been developed.

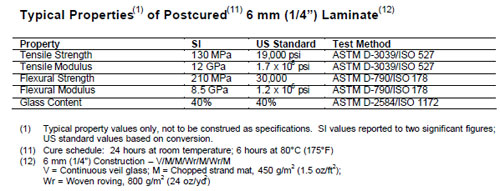

Vinyl esters have enhanced mechanical properties compared to polyesters with physical strength better impact and thermal shock resistance.

Characteristics of vinyl ester resins and networks such as shrinkage viscosity crosslink density glass transition temperature gel swelling and toughness have been studied.

High density cross linked products are suitable for temperatures above 250 of 121 oc.

Vinyl ester resins offer increased strength corrosion resistance and durability and are used in a wide variety of applications.

Properties epoxy vinyl ester resins ver are an important class of high performance thermoset molding resins.

The shrinkage of vinyl ester resins during cure was calculated according to density measurements to be 4 10 depending on styrene content.

Essentially they comprise a base of polyester resin strengthened with epoxy molecules in the backbone of the molecular chain.

It has greater strength and mechanical properties than polyester and less than epoxy resin.

Advances in fire retardant materials 2008.

Vinyl resins are often used in repair materials and laminating because it is waterproof and reliable.

For laminating process vinyl ester is usually initiated with methyl ethyl ketone peroxide.

They are produced by the addition of α β unsaturated carboxylic acids to epoxy resins.

Vinyl ester resins vinyl esters are halfway between polyesters and epoxies as far as typical properties and toughness and they are a step up on a cost basis.

Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid.